“Temperature is the single most important factor that affects flower value. Therefore, keeping flowers in low temperatures from the farm to the final destination is vital. Among the key areas of consideration is the transport from the farm to the airport. A well known and an increasingly more used tool to achieve this is the use of insulated refrigerated bodies.

“Temperature is the single most important factor that affects flower value. Therefore, keeping flowers in low temperatures from the farm to the final destination is vital. Among the key areas of consideration is the transport from the farm to the airport. A well known and an increasingly more used tool to achieve this is the use of insulated refrigerated bodies.

These systems are known to be durable and most energy efficient way to cool flowers. However, it is of utmost importance on whom and how it is incorporated in your cool chain.” This is explained by Mr. Ross G. Field of Specialized Fibreglass.

“We built our reputation and success on design excellence, quality control, and customer service. In this competitive market we have remained to be cost efficient and price competitive too, but not at the expense of quality”, says Mr. Ross Field. Therefore, using Specialized Fibreglass Ltd insulated bodies has some major advantages compared to others

Advantages

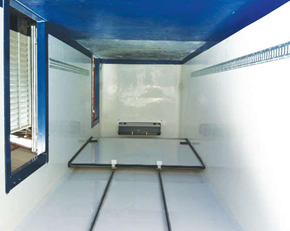

“The main advantages of our insulated bodies is the fact that we have many variations and customer options available, our insulation vary from 50-115mm, joints are laminated both inside and outside and the bodies are fitted with imported refrigeration units moulded on the vehicle engine for power or independent diesel units which have own independent engine (Customers can choose between the two). Customers also have the option of double or single doors fitted with imported seals and locking gears.

The bodies are also fitted with air curtains to ensure air does not get inside when opening to drop. “We also fit ribbed floors and side wall to promote air flow and have temperature controlled on the whole body’’, adds Mr. Field. The bodies are built to meet the Kenyan and by extension East Africa road transport specifications which are slightly different from the European requirements. Though there is a standard body, but if a customer wants some custom – made item – new concept or perhaps a modification of an existing design it will be done. Some of the special requirements may include longer, wider or higher bodies to cater for the number of boxes a grower wants to transport. These bodies range from 1 tonne pick up to 40 tonnes trailers and stand alone units.

The bodies are also fitted with air curtains to ensure air does not get inside when opening to drop. “We also fit ribbed floors and side wall to promote air flow and have temperature controlled on the whole body’’, adds Mr. Field. The bodies are built to meet the Kenyan and by extension East Africa road transport specifications which are slightly different from the European requirements. Though there is a standard body, but if a customer wants some custom – made item – new concept or perhaps a modification of an existing design it will be done. Some of the special requirements may include longer, wider or higher bodies to cater for the number of boxes a grower wants to transport. These bodies range from 1 tonne pick up to 40 tonnes trailers and stand alone units.

Supermarkets in Europe and other market places give temperature specifications to the grower in most cases temperatures between 20c to 40c. They insert data loggers in one of the boxes (small sensing computerized device) to ensure the client maintains those temperatures across the chain. A proper cool chain is highly important for maintaining high quality flowers and ensuring the grower gets maximum benefits. The use of a Specialised Fibreglass Ltd insulated bodies will ensure this. Guarantee Specialised Fibreglass Ltd customers are assured a one year’s warrant in all parts in addition to training staff that use the products. They also offer unrivalled after sales service especially on the refrigeration units. In addition they repair the bodies incase of accidents and minor accidents.

Why is cooling at origin more effective?

The reason why the cooling during transportation from the farm to the airport is important, is at the destination cooling only, is not as effective as it is done too late. “When recooling the flowers in destination, flowers have already been exposed to very high temperatures, free moisture / high ethylene levels and for a long transit time (to Europe). In this time, botrytis has been allowed to develop and there is no way back”, says a grower who requested anonymity.”

The reason why the cooling during transportation from the farm to the airport is important, is at the destination cooling only, is not as effective as it is done too late. “When recooling the flowers in destination, flowers have already been exposed to very high temperatures, free moisture / high ethylene levels and for a long transit time (to Europe). In this time, botrytis has been allowed to develop and there is no way back”, says a grower who requested anonymity.”

Adding, “This enables the flowers remain cooler during transportation and have a higher quality when they arrive at their destination. The process reduces the undesired exposure, which not only reduces losses, but also enables the flowers to reach their destination in the required quality”.

About Us

Operating since may 1981, Specialized Fiberglass Ltd is a house hold name in Kenya, a recognized brand of excellence in the moulding on a wide range of GRP (fiberglass) products in Kenya, with a brand in fields of vehicle bodies, boat building and architectural components, as well as an assortment of other items including a variety of tanks, carrier boxes for bicycles and motorbikes.

The largest and best known parts of SF’s market bodyworks (“the best bodies in town”), ranging from roof hatches for safari and tour vehicles, to rear canopies for pickups to specially insulated containers for refrigerated trucks and pickups.

We ensure close attention to specifications and quality of fittings and finishes to suit every client’s requirements as our priority.

The versatility of fiberglass means that almost anything can be moulded from it and technically there is nothing that Specialised Fibreglass Ltd cannot make, as a one – off unit or for mass production. “There are obviously cost-saving advantages in off-the –peg designs, and these have also been thoroughly tested and often refined and improved over time”. “But if a customer wants some custom-made item-a new concept or perhaps a modification of an existing design, that can be done too”.

The versatility of fiberglass means that almost anything can be moulded from it and technically there is nothing that Specialised Fibreglass Ltd cannot make, as a one – off unit or for mass production. “There are obviously cost-saving advantages in off-the –peg designs, and these have also been thoroughly tested and often refined and improved over time”. “But if a customer wants some custom-made item-a new concept or perhaps a modification of an existing design, that can be done too”.

“There is no mystique to the chemistry of fiberglass. It is attention to detail and finish that makes the difference”.

“We have built our reputation and success on design excellence, quality control, and customer service. In a competitive market we have to be cost efficient and price competitive too, but not at the expense of quality”.