Bʏ Mᴀʀʏ Mᴡᴇɴᴅᴇ,

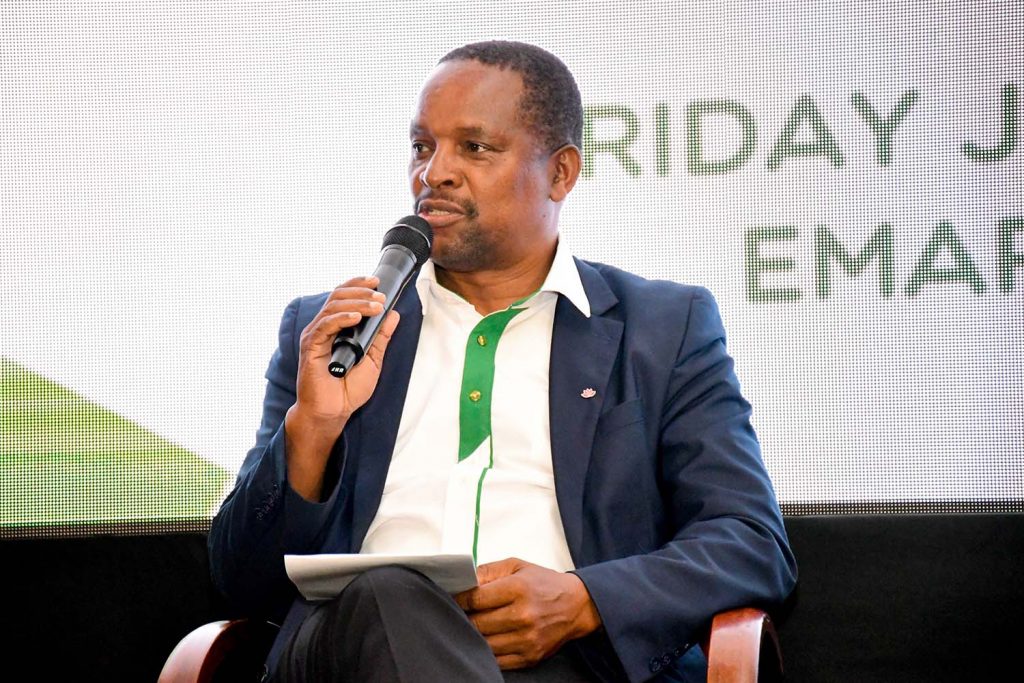

Kenya’s horticulture export industry faces mounting risks in key destination markets, with pest infestations, documentation errors, and pesticide residue violations driving a sharp increase in consignment interceptions. This was the warning from Dr. Josiah Syanda of the Kenya Plant Health Inspectorate Service (KEPHIS) during the Fresh Produce Exporters Association of Kenya (FPEAK) forum on sustainability and compliance, held as part of FPEAK’s 50th anniversary.

Kenya, having ratified the World Trade Organization’s Sanitary and Phytosanitary (SPS) Agreement in 2010, is obligated to implement strict plant health controls to safeguard international trade. “It is not because we like limiting businesses. It’s because the law at the international level requires that we intervene in the event there is non-compliance on matters of plant health,” Dr. Syanda explained.

Pest Interceptions Escalating

In 2024, Kenya recorded 43 pest-related interceptions: 19 involving flower consignments and 24 from fruits and vegetables. Thrips, particularly in herbs and flowers, were the leading cause.

“We have seen emerging pests like the false codling moth, we have seen an escalation of thrips, majorly on herbs and flowers, which never used to be the case,” Dr. Syanda noted.

He warned that importing countries are increasingly unwilling to tolerate contaminated consignments. “The importing countries have made it clear that they don’t want those pests entering their territories. If you have them in your produce, keep them within your borders,” he explained.

Failure to manage these pest issues effectively, he cautioned, not only leads to interceptions but places Kenya’s horticulture export reputation at risk of restrictive measures.

Beyond thrips, other pests of concern include African bollworm, fall armyworm, leaf miners, whiteflies, and the false codling moth (FCM) which are increasingly associated with higher interception rates, especially in herbs and ornamentals.

Documentation Failures a Growing Concern

Documentation errors overtook pest-related interceptions in 2024, with 77 consignments intercepted due to missing, incomplete, or inaccurate paperwork.

“If you have done very well on the farm and your produce looks like it has makeup and you mess up on documents, it will be rejected. It will be intercepted,” Dr. Syanda said.

He highlighted the most common mistakes: missing phytosanitary certificates, missing additional declarations, certificates getting lost during transit, or last-minute adjustments to consignments without corresponding updates to paperwork.

“When integrity checks are conducted to compare the documents against the consignment, any discrepancies such as unrecorded extra boxes, And whenever that happens, I’m the one held responsible and called to account.” he said.

Such incidents, he warned, are not only costly for individual exporters but damage the reputation of Kenya’s entire horticulture export sector, risking future trade disruptions.

MRL Violations Rising

Another escalating problem flagged by KEPHIS is non-compliance with Maximum Residue Limits (MRLs) for pesticide use. In 2023, Kenya received 50 notifications from importing countries for consignments exceeding allowable pesticide residue levels. In 2024, that figure increased sharply to 80.

“We have to wear the lens of health and safety. Compliance isn’t optional, it’s the foundation for accessing premium markets,” he emphasized.

While beans and peas have traditionally been the main focus of MRL-related interceptions, recent notifications now implicate capsicum, chives, and various herbs crops that had previously recorded minimal residue issues. Dr. Syanda warned that without tighter management of pesticide use and proper adherence to pre-harvest intervals, growers risk further market restrictions.

Industry Fragmentation Weakening Export Competitiveness

Unlike competitor countries that consolidate export volumes through organized producer groups and aggregation centers, Kenya’s horticulture sector remains highly fragmented, with individual growers sending small, uncoordinated consignments. “What I see from the gate where I sit, I see a lot of attempts. People in Kenya, they’re very resilient. And I see a lot of attempts for them to get their product to the market. But they are getting the product to the market in a very fragmented way. Somebody is placing 20 boxes, one box, ten boxes, trying to get to the market,” Dr. Syanda observed.

He called for the establishment of aggregation centers to consolidate export volumes and align compliance management. “These aggregation centers are where you can put together produce that can be regarded as produce of Kenya, which can meet the market demands,” he advised, adding that fragmented exports not only make compliance monitoring difficult but raise the unit cost of meeting export standards, especially for small and medium-scale producers.

Shift from Policing to Proactive Compliance

KEPHIS plans to work more closely with growers and exporters by providing technical guidance earlier in the production chain. “We need to bring the science to you in a synthesized way not wait to tell you at the gate that you are non-compliant,” Dr. Syanda said.

This, he said, would involve closer collaboration between regulators, growers, exporters, and industry associations such as FPEAK to simplify complex phytosanitary requirements and integrate them into production routines early on.

“The agriculture that we were doing in the 60s and 70s is no longer what is happening today. The challenges of today are more than that. Climate change, sustainability, the need for compliance, the new demand for the consumer that demands you as a producer to comply and conform to those ones,” he noted.

He called on the industry to self-regulate, noting the growing reputational risk if compliance failures persist. “We must self-regulate. If we don’t, we risk jeopardizing the access we’ve worked so hard to secure,” he warned.