Across the floriculture industry, retailers are facing a quality challenge, with exciting opportunities in its wake. With the flower market growing rapidly, flower sellers will flourish with stable supply chains and dependable quality levels; however, today’s retailers, from independent family stores to national supermarket chains, too often receive flowers of inconsistent quality: regularly, batches are unacceptable, with a short vase life, damaged stems, and flowers that are not worth selling due to poor quality on arrival. This leads to unhappy customers and loss of reputation and revenues. Alongside broader industry concerns, like reduced air freight capacity, this problem can significantly limit growth. So where’s the opportunity? It’s right here, and it centers on implementing data-driven quality standards throughout the flower supply chain.

Across the floriculture industry, retailers are facing a quality challenge, with exciting opportunities in its wake. With the flower market growing rapidly, flower sellers will flourish with stable supply chains and dependable quality levels; however, today’s retailers, from independent family stores to national supermarket chains, too often receive flowers of inconsistent quality: regularly, batches are unacceptable, with a short vase life, damaged stems, and flowers that are not worth selling due to poor quality on arrival. This leads to unhappy customers and loss of reputation and revenues. Alongside broader industry concerns, like reduced air freight capacity, this problem can significantly limit growth. So where’s the opportunity? It’s right here, and it centers on implementing data-driven quality standards throughout the flower supply chain.

In this article, we explore how this answer provides a guarantee of high-quality flowers, supporting our claim by revealing statistics about today’s quality leaks in the floriculture industry.

The Price Of Poor Quality: Unpredictable Flower Supply Chains Are Costing Retailers Customers And Money

Compared with other supermarket product groups, flowers often have the highest complaints per million units (CPMU) in retail – a clear sign of underperformance across the floriculture industry. In our own extensive research on four European retailers from Germany and the Benelux region (Belgium, the Netherlands, Luxemburg), we found that flower quality is often poor and usually inconsistent. In fact, the data shows that close to onequarter of flowers are not worth selling on arrival.

Start test

FIG 1: Average proportion of flowers suitable for sale on arrival for three European retailers

This lack of quality has significant implications for retailers, including:

- Losing money on unsold flowers, struggling to make a profit or break even

- Excess waste, harming your business and the environment

- Unhappy consumers, leaving your business and spreading negative messages online

Why is quality so inconsistent in floriculture?

The fact that quality is always under pressure in this business is not surprising: flowers are a highly sensitive, fragile product, especially when shipped around the world on aeroplanes, ships, and trucks. The smallest misstep somewhere in the supply chain linking farmer to florist can hugely impact a flower’s vase life and quality. There are numerous areas in which these missteps are easily made. Two important areas are packaging and cold chain management. While there are excellent growers and exporters in the industry, there are also many whose practices, often carried out without clear and effective quality standards, reduce flower quality.

Testing offers clear evidence of all this. While traders may perform free vase life tests for their retailers, the outcomes are not followed up by improvement measures. One solution we recommend is testing by a third party. An independent expert can test farms at a higher frequency, allowing retailers clear insight into performance levels. And, with organized databases, a third party can offer data-driven decision-making and insight at the lowest possible cost.

The numbers behind the quality challenge

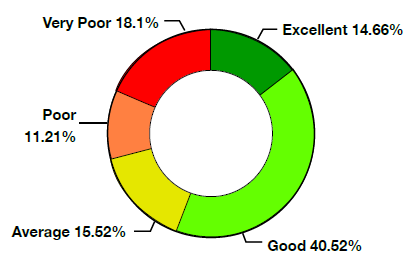

Our own, independent tests show that flower quality is often poor, and wildly inconsistent. Below, figure 2 shows the average flower quality breakdown across the four retailers we inspected: as you can see, very poor to poor batches make up close to 30%, while excellent quality flowers remain a rarity.

FIG 2: Overall quality breakdown across batches on arrival, from excellent to very poor, for three European retailers

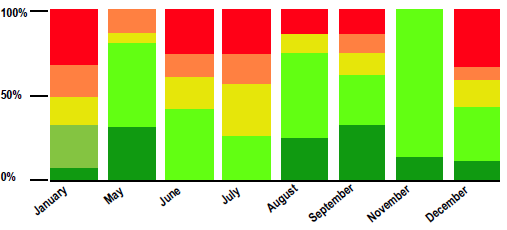

As for quality inconsistency, figure 3 shows how flower quality for these retailers greatly varies across the year, with the busiest months seeing high levels of poor to very poor flowers.

FIG 3: Flower quality variation across an eight-month period for three European retailers

For today’s flower sellers, this poses a significant question: how can retailers manage this level of quality inconsistency and underperformance? Any 25% loss is worth tackling While flowers represent a relatively small share of a retailer’s turnover, poor flower quality clearly harms business. Any 25% loss is worth tackling. So what real solutions are there for this quality challenge? How can you make sure the flowers in your supermarkets come to represent the kind of premium, consistent quality that will encourage consumers to talk favorably about your brand? Our answer: data and standardization. Through this, retailers can guarantee higher quality flowers, saving money and ensuring happier customers.

There are numerous areas in which these missteps are easily made. Two important areas are packaging and cold chain management. While there are excellent growers and exporters in the industry, there are also many whose practices, often carried out without clear and effective quality standards, reduce flower quality.