The Covid-19 pandemic is highlighting the supply chain problems which can arise when border clearance arrangements come under stress from increased demands and reduced capacities. This is bringing into question the future commercial viability of existing ACP triangular supply chains for short shelf life products in serving the UK market.

The Covid-19 pandemic is highlighting the supply chain problems which can arise when border clearance arrangements come under stress from increased demands and reduced capacities. This is bringing into question the future commercial viability of existing ACP triangular supply chains for short shelf life products in serving the UK market.

This needs to be seen in the light of the border clearance challenges and associated transportation disruptions which are likely to arise as a result of the UK governments’ current approach to future trade relations once it leaves the EU customs union and single market. Current policy responses to transportation disruptions associated with border clearance problems linked to the Covid-19 pandemic, could provide a basis for longer term arrangements to facilitate the continued smooth functioning of triangular supply chains. In the absence of such initiatives ACP exporters will need to explore opportunities for direct exports to the UK or diversification away from the UK market.

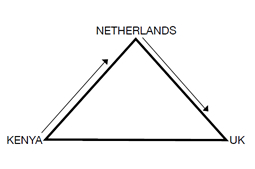

The impact of these disruptions could prove particularly severe for ACP producers of short shelf life fruit, vegetables and cut flowers exporting to the UK along triangular supply chains. This is vividly illustrated by the impact of the Covid-19 pandemic on Kenyan cut flower exports. Press reports indicated ‘exports to Holland were suspended’ with ‘only flowers meant for supermarkets’ in the UK being shipped.

This strongly suggests that at a time of border clearance delays and associated transportation disruptions the more direct and shorter the supply chain the better. Against this background it is worth reviewing some of the short-term trade effects of the current Covid-19 pandemic, in light of the possible lessons this experience could provide for dealing with a ‘hard Brexit’.

• Cost Increases: Reefers Border clearance and associated transportation disruptions linked to the Covid-19 pandemic is seeing refrigerated containers (reefers) being tied up in unproductive delays. This is resulting in an increase in the costs of leasing refrigerated containers. On average in recent weeks these prices have increased been between 30-50%. However, for short term leases these price increases have been of the order of 200%. This is serving to increase the costs of moving cargoes onward to the UK market along triangular supply chains. This is compounding the problem of getting cargos to Europe in the first place, given the reduction in scheduled commercial airline services on which, on average, around 80% of air freighted cargoes are shipped.

• Cost Increases: Vehicle and Driver Availability

Border clearance delays and driver fears of being caught away from home as further border restrictions were introduced, saw a shortage of drivers emerging for transport services along certain routes, particularly to Italy, the initial European centre of the Covid-19 outbreak.

Similarly, the prospect of delays at UK ports arising from the reintroduction of customs and other border controls on EU27/UK trade would seem likely to make individual drivers and smaller haulage operators reluctant to contract for cargoes for delivery to the UK for fear of losing out on further contracts through both drivers and trucks being caught up in port congestion and traffic delays in the UK. This is likely to drive up the cost of onward shipment of cargoes from initial ports of landing in an EU27 member state to the UK market. It could even lead to an absolute shortage of drivers and trucks along routes serving the UK market.

This however could potentially be eased by moving over to unaccompanied freight movements (including greater use of railways). This is already happening to a certain extent in response to the Covid-19 pandemic. This would however be likely to lead to longer unloading times than is currently the case, and as such could prove problematic for ACP short shelf life products.

• Loss of Value

For short shelf life products, delays in border clearance, alongside possible traffic congestion and any possible additional phytosanitary checks upon entry to the UK market, could serve to strip value out of the supply chain as the in-shop shelf life of delivered products is reduced. This loss of value could come to fall on the shoulders of ACP exporters using triangular supply chains, depending on the nature of the individual supply contracts ACP exporters have entered into (i.e. at which point along the supply chain the ACP exporter takes payment).

• The Need to Get to Grips with Challenges Faced

These are three of a multiplicity of factors which would be likely to erode the benefits of using single distribution hubs in Europe in serving just-in-time supply chains in the UK and could bring the future use of such supply chains into question.These problems have been brought into focus as a result of the Covid-19 pandemic, with similar problems likely to become a structural feature of UK-EU trade relations in the coming years. According to Bobbie Ttooulis, executive director at Global Freight Solutions, ‘long delays at the ports are going to be part and parcel for this new Brexit reality’. Against this background it is crucial for businesses to identify the ‘changes to border procedures, documentation, duties, taxes and pressures that will impact their supply chains’.

ACP exporters of short shelf life products to the UK market along triangular supply chains will be unable to avoid these challenges unless specific arrangements are set in place to facilitate the continued smooth functioning of triangular supply chains.

In addition it should be noted how the current intensification of dialogue between the UK government and the UK food industry underway as a result of the Covid19 pandemic has highlighted how ‘UK food makers are relatively well-prepared to weather the storm, in no small thanks to the preparations already being made due to concerns over a potential no-deal exit from the European Union’. Preparations for a ‘hard Brexit’ have seen UK food businesses reviewing the functioning of their supply chains to ‘identify where alternative supplies of ingredients can be sourced’, should existing supply chains be disrupted.

The Covid-19 pandemic is thus likely to accelerate an existing process where UK wholesalers and retailers are actively reviewing their supply chains to reduce their vulnerability to transportation related disruptions. This suggests ACP exporters using triangular supply chains could become less favoured sources of supply, given the perceived dangers of supply chain disruptions.

This suggests a need for ACP exporters to actively explore their options for:

- The direct shipments of short shelf life products to the UK market;

- Diversification away from the UK market; or

- Contractual arrangement for the supply of goods to EU27 importers which ensure payment for delivery to the first port of unloading in the EU, with any risk of on-transportation disruptions being carried by the EU27 re-exporter.

This will be particularly important if no administrative and border clearance facilitation arrangements are set in place to ensure the continued smooth functioning of existing ACP triangular supply chains. However, for a range of smaller ACP exporters some form of market adjustment support may be needed if they are to continue to profitably serve export markets in Europe.